ERP.Production Ц Version for the Fishery and Fish Processing Industry

The ERP.Production solution allows to plan, control, analyze and

manage production processes of industrial enterprises.

Production processes even in one

industry differ greatly depending on the manufactured products.

Products are usually diverse in kinds and types and, moreover, often

go through a number of stages during the life cycle, therefore the

enterprise requires different management models. Support of the full

product life cycle is carried out from production to sale or

write-off.

Volume-calendar planning based on

requests makes it possible to plan production and form plans based on

existing sales orders and availability of critical components

(materials) and production equipment.

Material requirements planning

allows, when launching a request into work, to calculate the needs

for all materials and raw materials, taking into account warehouse

stocks, planned receipts and shipments. The named needs arise on the

basis of sales orders, shop orders, work orders (repairs). This

information is compared with unreserved stocks, supply orders and

shop orders to determine the need for raw materials and components.

The task of capacity

requirements planning consists in determining the real сроки of

execution of the production program on the available production

capacities. Planning the load of work centers facilitates the process

of determining possible bottlenecks and allows smoothing underload

and overload of production capacities and personnel.

One of the results of the module

operation are the requests generated by the system for creation of

shop orders and supply orders. Orders are created on the basis of

acceptance or adjustment of requests.

Work instructions (technical

conditions for performing operations) for execution of the order can

be added to a shop order, as well as components can be added or

excluded.

Informational messages about the

threat of overdue delivery date of a sales order due to delays in

supply and execution of shop orders are provided.

Product cost control.

Standard cost (standart

costing). When calculating it, they are guided by the provisions that

planned values are based on the forecast, direct variable costs are

planned by product types, other costs by cost centers. Cost

calculation is performed for a standard batch size or production

cycle.

Process cost (activity based

costing) - unlike standard cost, uses the parameters of the process

of creating added value as a result of consumption of various

resources. For non-standard products, for which production

preparation, design and technological elaboration, several cycles of

equipment setup may be required, it is possible to define the listed

processes as sources of process costs.

The possibility of combining

standard and process cost in one hybrid cost model is provided.

Calculations according to the above cost models are carried out on

the basis of summing cost elements and take into account the data of

the specification and technological route, as well as the

technological process. The calculation contains estimates of costs of

this level of production and all lower ones down to purchased

components and raw materials.

The current calculation of

production costs by order reflects the registered volume of work in

progress by order. On its basis, the current production situation can

be analyzed and corrected based on the analysis of reasons for

deviations from the preliminary cost calculation. Operational

functional cost analysis of production makes it possible to quickly

see where deviations begin.

Analysis of the operation of

production with a wide assortment of goods and large turnover is very

difficult and requires a large amount of time. Correctly setting

priorities is helped by the ABC-analysis method ( Activity-Based

Costing ), with the help of which it is possible to immediately

identify that group of 20 percent of goods that bring 40 percent of

income, and to identify those 10 percent of goods that bring 5

percent of income and take away 25 percent of production capacities.

Brief list of capabilities of

the ERP.Production module

Х Production output planning

-

using graphical tools to

optimize the loading of production capacities,

-

with creation of a list of

necessary components,

-

with creation of a list of

performed works and necessary human resources,

Х Control over the production

process by sections by:

-

movement of components by

performed orders using multi-level analysis by types and names,

-

components consumed for

production, with analytics of planned and actually spent funds,

both by period and cumulatively,

-

wages, including piecework

or time-based wage calculation, with analytics of planned and

actually spent time and funds, both by period and cumulatively,

-

analytics of obtained

products ( defects, returns to production, rejection ).

-

constant expenses for

activity ( rents, leasings and so on ), with analytics of planned

and actually spent funds, both by period and cumulatively,

-

taxes, with analytics of

planned and actually spent funds, both by period and

cumulatively,

-

issued invoices and their

payment;

Х The obtained data have

possibilities:

-

analysis of the production

cycle for any period, as well as step-by-step and by-order, with

obtaining results for a certain date, with analysis of cost and

prime cost,

-

analysis of several forms of

activity,

-

analysis of sub- or general

contracts, with analytics of planned and actually spent funds,

both by period and cumulatively, of deadlines for execution of

works;

Х Possibility to оперативно

assess the economic condition of the enterprise, the economic benefit

from a specific executed order or form of activity of the enterprise;

Х Archive of all documentation

without limitation of their storage period;

Х Fast finding in the archive of

information by various attributes (order number, job order,

configuration, client, invoice number and so on) ;

Interaction of WMS.Management

and ERP.Production is built on the principle of their full

integration, in particular , when issuing finished products from

production, the corresponding warehouse receipt document is

automatically created, when issuing raw materials to production, the

corresponding document on acceptance of raw materials into production

is automatically created. For transferring requests for production

and internal issue within the enterprise, an internal document

transfer system with sound notification, with analysis of execution

and with control of unfulfilled orders is used.

The delivery set includes

adaptation to the conditions and needs of a specific enterprise,

installation, setup and full staff training with subsequent 1 year of

software support.

The cost of the software complex

is determined individually for each company, depending on the volume

of adaptation works and the number of workplaces, the required

composition of the complex.

If the client wishes, we will

develop a full or limited web interface, using modern web

technologies. More detailed information is at the link Application in

production and warehouse complexes.

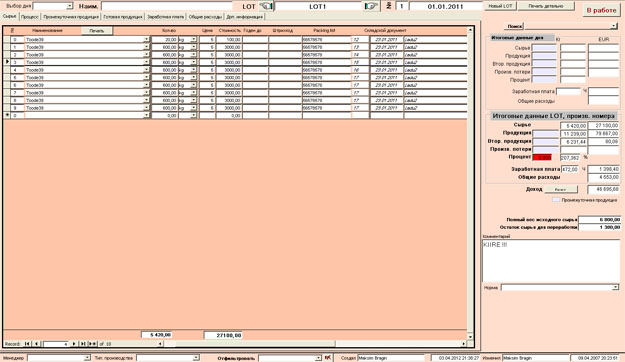

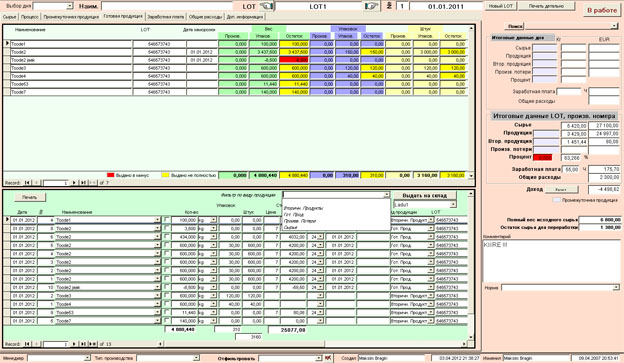

Form for entering raw materials into the technological

process. In the left part of the form, the warehouse document is

visible, according to which the raw materials were issued to production,

with the possibility of quick переход to it by double click. In the

right part, at any moment of work with the production module, the main

parameters of the production cycle are shown.

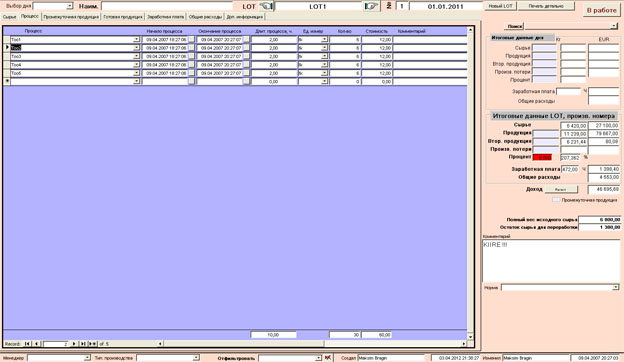

Form for entering data on the technological process.

Form for forming packaged finished products. By the

"Issue to warehouse" button, automatic issuing of finished products to

the production warehouse or to the trading warehouse is performed. In

the right part of the form, the warehouse document is visible, according

to which the finished products were issued, with the possibility of

quick переход to it by double click.

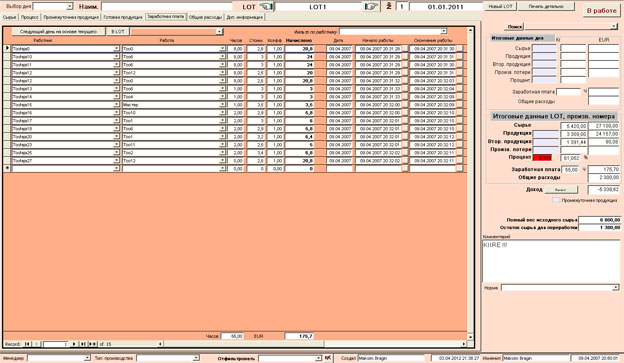

Form for entering wage data into the technological

process.

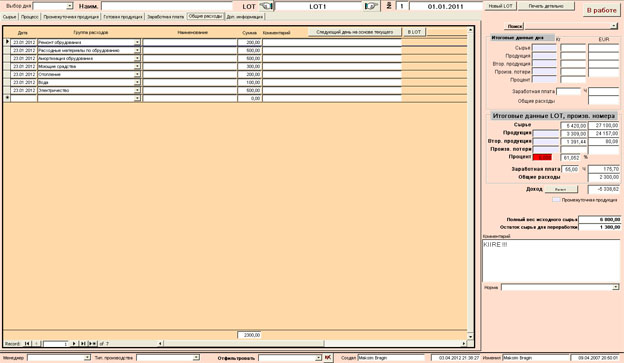

Form for entering general expenses into the

technological process.

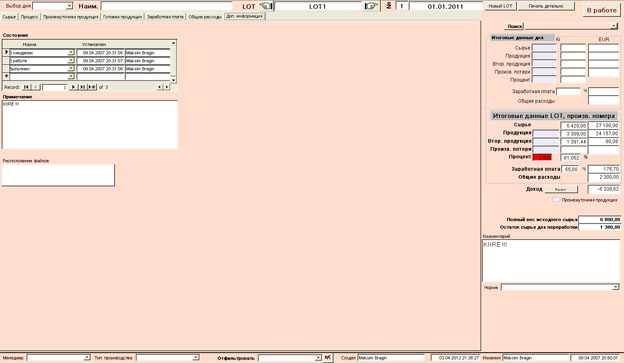

Form for entering additional information into the

technological process.

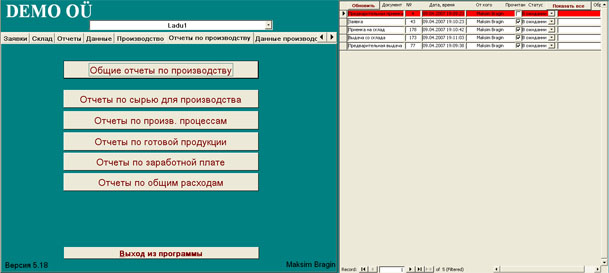

Production reporting form.

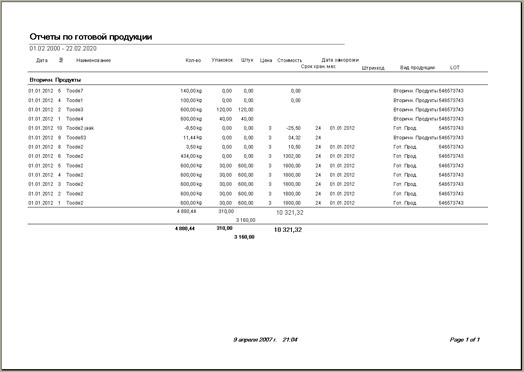

Query form for finished products.

One of the variants of the finished products report.

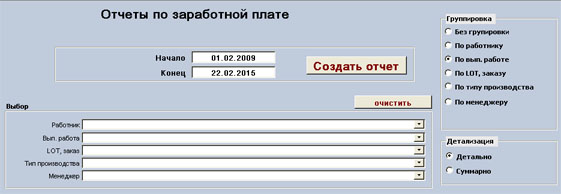

Query form for wages.

NB ! All

data given in the demonstration forms are fictitious and any

coincidences are accidental.

The software

is developed using Microsoft Access and Microsoft SQL Server.