WMS.Management, version for the Fish and Fish Processing Industry

Modern

requirements for warehouse services demand more service in less time. A

sharp increase in processing speed and a significant reduction in errors

is achievable by implementing the specialized WMS.Management software

suite—an automated Warehouse Management System (WMS).

Key features:

-

Operations accounting:

goods receipt, shipment, return, internal transfers, write-offs,

reservation of goods for sales orders, purchase orders to suppliers.

-

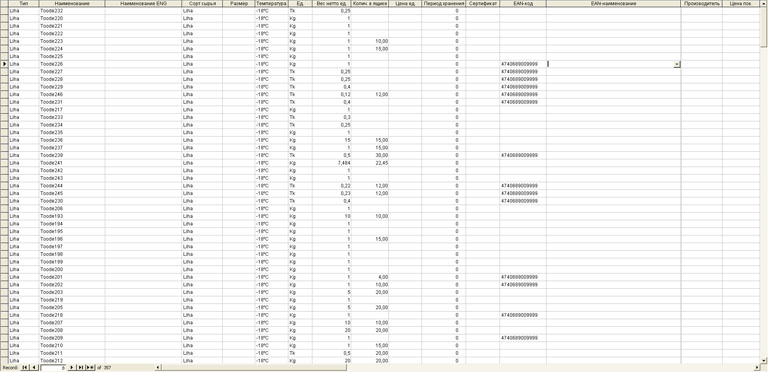

Advanced turnover and stock

analytics by industry-specific parameters—fish size, fish

and raw material grade, storage temperature, shelf life, and

expiration date.

-

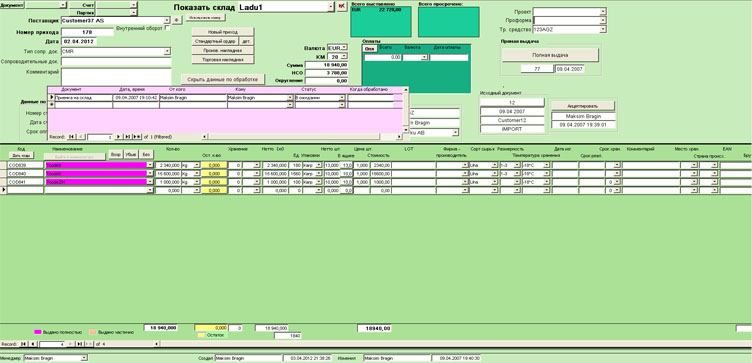

Automatic direct

warehouse-to-warehouse transfers with the click of the

“TRANSFER TO WAREHOUSE” button, reducing input time to seconds—for

example, transferring from a terminal to a customs warehouse, from

customs to free storage, regardless of the quantity of goods;

includes authorization for receipt of goods, cash and non-cash

payments, etc.

-

Client and supplier account

management.

-

Printing of all relevant

documents—invoices, delivery notes, price lists, labels, and

other documentation.

-

Extensive reporting system:

information directories for analyzing receipts, shipments,

write-offs, sales, reservations, orders, inventory movements,

profits, costs, product turnover, debts to counterparties (including

accounting for goods taken on consignment), stock levels per

warehouse and supplier, product efficiency, and more.

-

Convenient search

in directories and fast document processing.

-

Corrective backdating of

documents.

-

Linking dependent

documents.

-

Multi-currency accounting.

-

Cost calculation for goods

using one of the following methods:

a. Weighted average

b. FIFO

(first in, first out), LIFO (last in, first out), FEFO (first

expiring, first out)

c.

First-cheapest, first; first-most expensive, first

-

Cost per warehouse

considering stock receipts from each supplier and production date.

-

Priority issuance of goods

with earlier production dates.

-

Data export/import

to other databases.

-

Multiple price levels

for each item with quick updates.

-

Integration with cash

registers.

-

Support for all barcode

scanners.

-

Label printer support

(for barcode printing).

-

Batch tracking,

unlimited barcodes per product, nested packaging, and more.

-

User-specific configuration

and role-based access control.

The

interaction between

WMS.Management and

ERP.Production is fully integrated: when finished products

are released from production, a corresponding warehouse receipt

document is automatically generated; when raw materials are issued to

production, the system automatically creates a corresponding

production receipt document. For internal production orders and

issue, an internal document transfer system is used with sound

alerts, execution tracking, and control of uncompleted orders.

Barcode scanning technology

is applied to increase processing speed. Barcode scanning also

significantly reduces human error: the error rate is only 0.03%—and

that only if the wrong item is picked despite scanning a barcode.

Human error cannot be completely eliminated, but checks at the

shipment stage ensure the client receives the correct order.

Optionally, the program can be adapted for

RFID devices.

Address-based storage

system: Users can see stock levels and exact storage

locations, down to individual cells on a warehouse map. Address-based

storage helps organize inventory, optimize stock levels, and reduce

internal warehouse movements. Graphical reports visualize item

locations to optimize picking. Address-based storage is

barcode-driven and organized via numbering of cells, pallets, and

items.

ABC analysis: For

warehouses with a wide range of products and high turnover, ABC

analysis helps prioritize items: identify the 20% of products

generating 80% of revenue, and the 20% of products generating 10% of

revenue occupying 80% of warehouse space.

User interface:

Can be customized to client needs (Estonian, Russian, English,

Latvian, etc.).

Integration with CargoPro:

Full integration with CargoPro for automated transportation

management. CargoPro is adapted for all types of transport—road,

rail, sea, and air—and for all types of cargo.

Optional integration with

Marketing and CRM modules: Allows systematic management of

marketing activities and individual client interactions, ensuring

smooth workflow from order submission.

Web interface:

Optional full or limited web interface can be developed using modern

web technologies.

Delivery package:

Includes adaptation to enterprise conditions, installation,

configuration, full staff training, and 1-year software support.

Demonstrations of WMS.Management capabilities can be arranged at the

client’s facility.

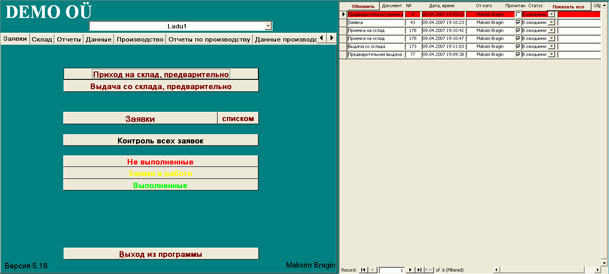

Main menu shows tasks to be completed on the right.

New tasks trigger a sound alert and highlight the row in red.

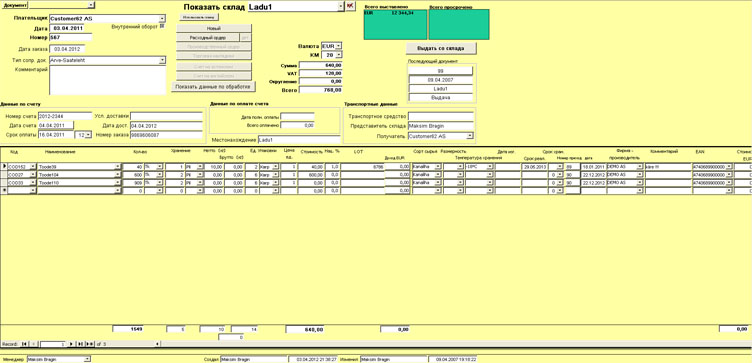

Preliminary goods receipt: items accepted with

“Receive to warehouse” button.

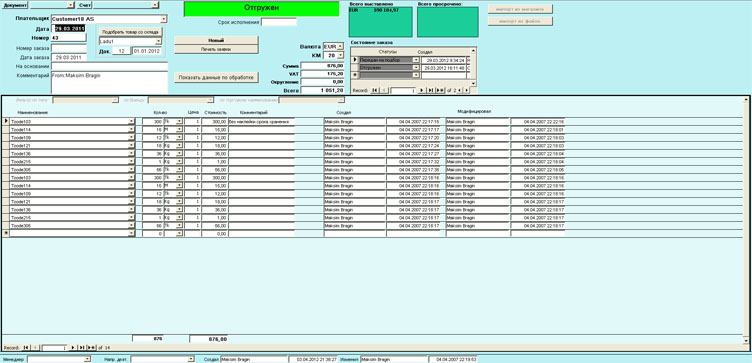

Preliminary goods issue: items issued with “Issue from

warehouse” button.

Order form: automatic selection by FIFO, LIFO, FEFO,

with transition to goods issue form.

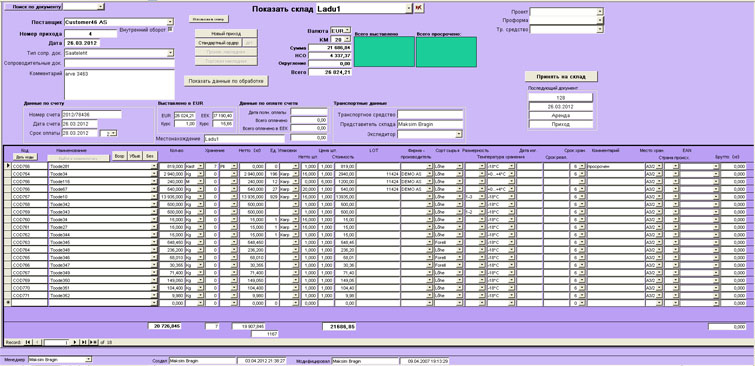

Goods nomenclature.

Warehouse receipt form.

Warehouse issue form.

Query forms for stock status.

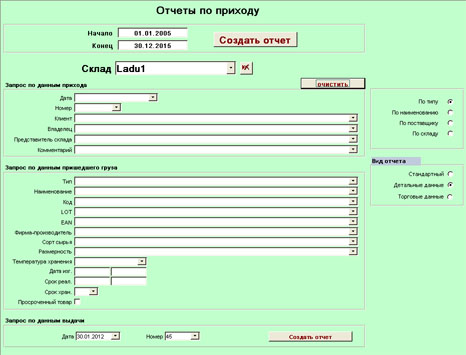

Query forms for stock goods receipt.

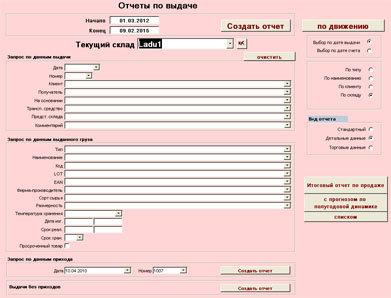

Query forms for goods issue reports.

Since this version is an extension of standard

WMS.Management, the other standard forms and reports can be viewed at

Warehouse Complex WMS.Management

NB:

All data in the demonstration forms is fictional; any resemblance to

real entities is purely coincidental.

|

|